Feature 2 Verification of accuracy

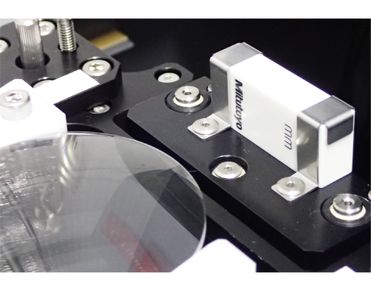

1. A block gauge built into the device

Comparative measurement with a block gauge built into the device

The way to increase the accuracy is to calibrate the instrument more often. This instrument has a built-in ceramic block gauge, which is programmed to automatically calibrate itself first before starting the actual measurement. Since the measurement is "reflective", it does not depend on the refractive index of the lens.

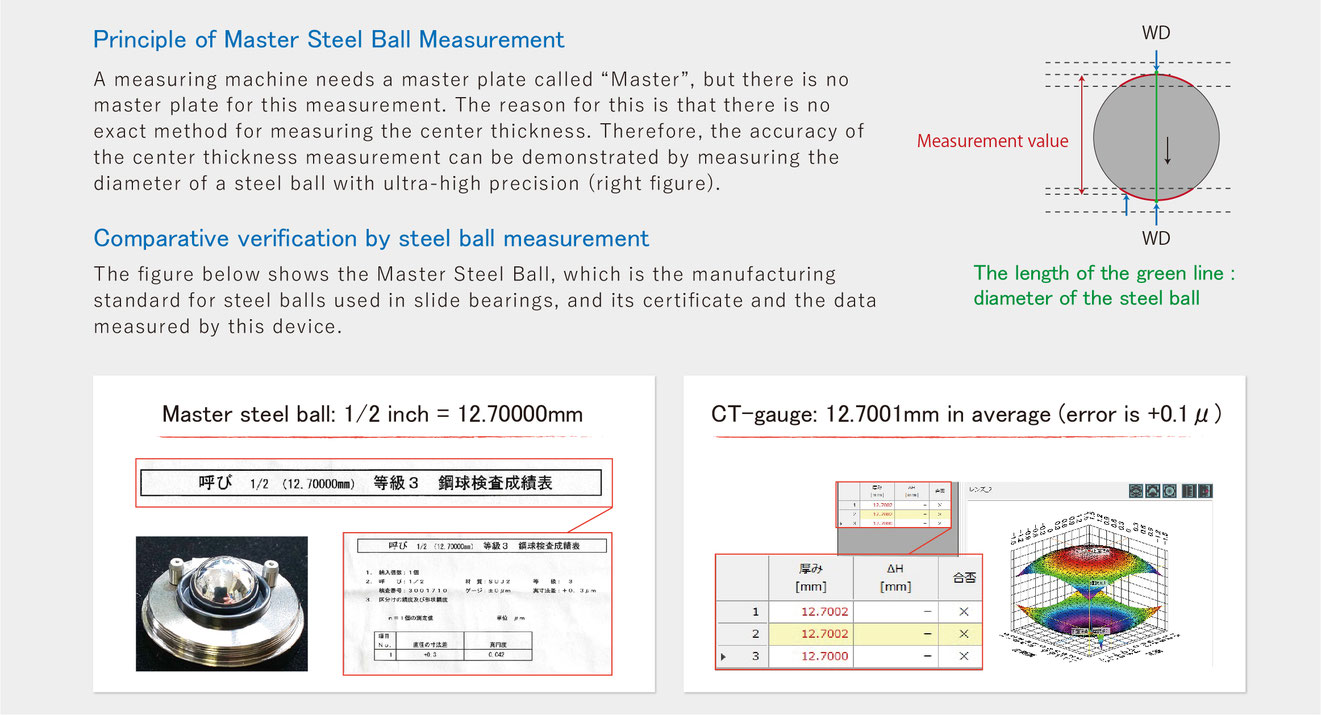

Verification of accuracy

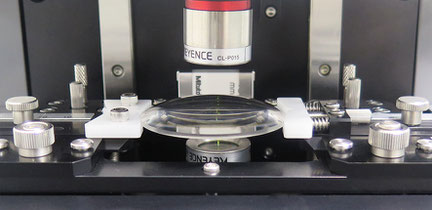

2. Mechanical mechanism

Mechanical mechanism to measure the center thickness of the lens correctly

In lens measurement, a "yatoi" is often used, but it is costly and time-consuming to manufacture one for each measurement. In this system, a lens holding mechanism that does not use a tool is available. In addition, orthogonality between the measurement light and the sample is important to measure the center thickness accurately with the reflection type.

Sample chucking mechanism

The lens holding mechanism is a V-shaped support made of Delrin material that can hold any diameter. Also, automatic vertex detection eliminates the need for centering and holding.

Available in diameters from 10 to 100 mm. *Individual holder is required for φ10 or less.

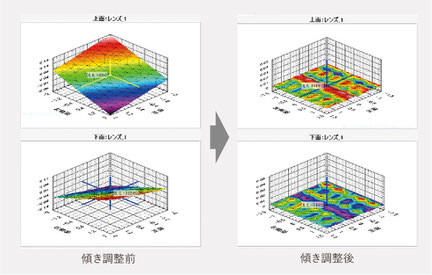

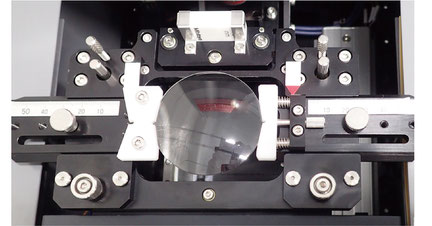

Check the level on a 3D map

Use the parallel plane plate to adjust the level of the sample holding surface.