CT gauge TOP (English)

Non-contacting

Lens Center Thickness Gauge CTgauge

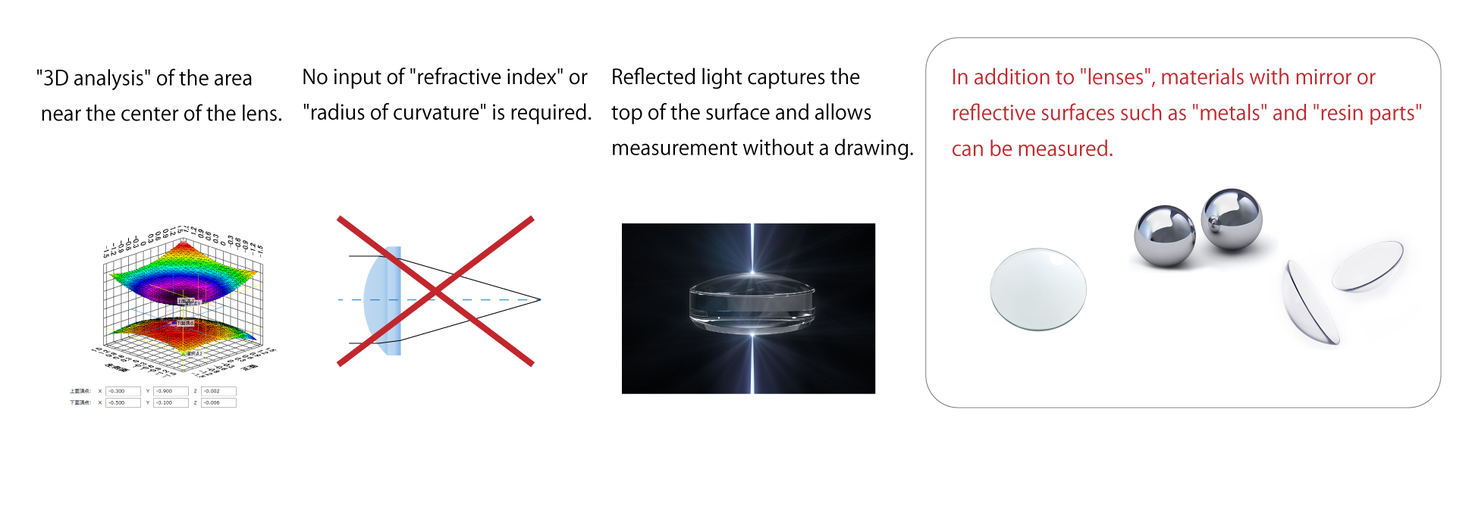

Non-contact automatic measurement without touching the lens

Although the center thickness of the lens is clearly indicated on the design drawing, it is difficult to measure accurately, and the "contact type" device is the mainstream. The accuracy of the "contact type" depends on the mechanical structure, and "measurement scratch" is also an issue.

Accurate and automatic “non-contact" measurement would be an ideal. This machine was developed in response to such requests.